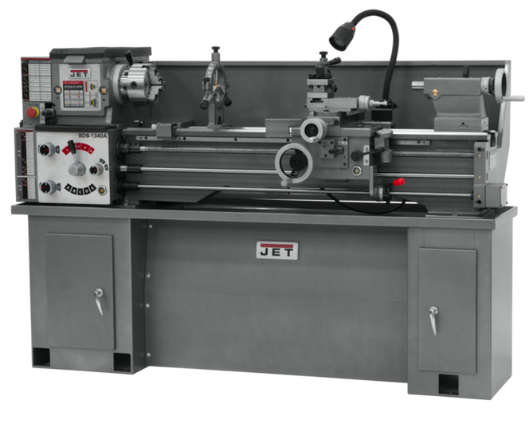

The Jet GHB-1340A Lathe includes a quick change gearbox for easy speed changes and a digital readout for precise speed control. This lathe is perfect for both professional and hobbyist woodworkers looking for a reliable and high-quality lathe.

Pros:

- Precision: Extremely accurate measurements.

- Versatility: Includes a taper attachment for a variety of turning operations.

- Powerful: High horsepower motor suitable for heavy-duty tasks.

- Durability: Robust construction ensures longevity and sustained performance.

- Ease of Use: User-friendly controls and an ergonomic layout.

Cons:

- Cost: Higher price point, which may be prohibitive for hobbyists or small shops.

- Size: Larger footprint requires more space, which might not be ideal for smaller workshops.

==>> It is currently in stock. Get it here from the best distributor

Personal Experience with Jet 321101AK GHB-1340A Lathe with CBS-1340A Stand

Having used the Jet 321101AK GHB-1340A Lathe for several months, I can personally attest to its performance and reliability. One of the first things that struck me was the smoothness of its operation. The enclosed gear box significantly reduces noise, which is a boon in a busy workshop where multiple machines might be running simultaneously. The precision roller bearings ensure the spindle runs true, allowing for high accuracy in all my machining tasks.

Practical Use Cases

In my experience, the Jet GHB-1340A excels in various applications, from small intricate parts to larger workpieces. The versatility of this lathe is evident in its ability to handle a wide range of materials. I’ve worked on everything from aluminum and brass to tougher metals like steel. The lathe's ability to maintain tight tolerances has been particularly beneficial when crafting parts that require a high degree of precision.

Performance Analysis

One of the standout features for me is the fast and easy speed changes. The eight available spindle speeds, ranging from 70 to 2,000 RPM, provide ample flexibility for different machining tasks. Whether I need a slower speed for a detailed finishing pass or a higher speed for roughing out material, the GHB-1340A accommodates my needs seamlessly.

The inclusion of both a 3-jaw and 4-jaw chuck, along with a 12″ face plate, has been a significant advantage. The 3-jaw chuck is perfect for holding round workpieces, while the 4-jaw chuck provides the flexibility to hold irregular shapes. This versatility has allowed me to take on a variety of projects without needing additional accessories.

Precision and Control

One aspect of the Jet GHB-1340A that consistently impresses me is its precision. The lathe's D1-4 spindle, supported by high-quality tapered roller bearings, ensures that every cut is accurate. This is crucial when working on parts that require tight tolerances. For example, when I was fabricating a set of custom engine mounts, the precision of the lathe allowed me to achieve a perfect fit, ensuring the components would perform reliably under stress.

The compound and cross slides are designed with backlash elimination, which significantly enhances control during intricate operations. This feature has been particularly useful when turning tapers. The ability to offset the tailstock and use the inch-metric graduated quill for precise adjustments means that I can achieve the exact taper angle required for each project.

Handling Different Materials

The Jet GHB-1340A's capability to handle a variety of materials is another standout feature. I regularly machine parts from aluminum, brass, and steel, and the lathe performs exceptionally well with all these materials. The hardened and ground gears in the headstock and gearbox, combined with the constant oiling system, ensure smooth operation and prolong the life of the machine.

One memorable project involved machining a set of custom pulleys from high-strength steel. This task required consistent cutting performance and the ability to maintain tight tolerances throughout the process. The Jet lathe handled the challenge admirably, producing high-quality components that were essential for the project's success.

Ease of Use

The lathe's user-friendly design makes it accessible for both novices and experienced machinists. The apron-mounted spindle actuation control offers a level of precision and ease that I haven’t found in other lathes I’ve used. Adjusting the gibs in the carriage and slideways is straightforward, ensuring that I can maintain optimal performance with minimal downtime for adjustments.

The tailstock, which can be offset for turning tapers, has been particularly useful. I frequently need to turn tapers for custom parts, and the inch-metric graduated quill allows for precise adjustments. The backlash elimination in the compound and cross slides also contributes to the overall accuracy and ease of operation.

Maintenance and Longevity

Maintaining the Jet GHB-1340A is relatively hassle-free. The constant oiling of the headstock during operation means I don’t have to worry about lubrication issues. Regular cleaning of the oil pan and checking the splash guard for debris are simple tasks that ensure the lathe continues to run smoothly.

The robust construction and high-quality materials used in the GHB-1340A give me confidence in its longevity. Even with regular use, the lathe shows no signs of wear, and I expect it to remain a key part of my workshop for many years.

Purchasing Experience from Beaver Industrial Supply

Purchasing the Jet 321101AK GHB-1340A Lathe from Beaver Industrial Supply was a seamless and positive experience. The team at Beaver Industrial Supply was incredibly helpful, providing detailed information and answering all my questions promptly.

The ordering process was straightforward, and the delivery was timely and well-coordinated. The lathe arrived in excellent condition, well-packaged to prevent any damage during transit. The customer service follow-up ensured that everything was satisfactory, making the entire purchasing experience smooth and stress-free.

Jet 321101AK GHB-1340A Lathe with CBS-1340A Stand Overview

In the realm of metalworking and precision engineering, a reliable and robust lathe is not just a tool but the backbone of the workshop. The Jet 321101AK GHB-1340A Lathe, coupled with the CBS-1340A Stand, promises to be a cornerstone for any machining enthusiast or professional. This review delves into its features, performance, and overall value to help you decide if it's the right addition to your shop.

Overview of Features

The Jet GHB-1340A is designed with meticulous attention to detail, evident in its robust construction and user-centric features. The lathe sports an enclosed gear box, ensuring smooth, quiet operation—a crucial factor for workshops prioritizing a noise-reduced environment. This gearing system not only enhances operational quietude but also facilitates fast and easy speed changes, thereby optimizing workshop efficiency.

Design and Build Quality

Encased in a finely engineered chassis, the Jet lathe's headstock and gearbox feature hardened and ground gears, reducing wear and maintaining precision over long periods. The D1-4 spindle, supported by high-quality tapered roller bearings, enhances the lathe's ability to hold tight tolerances, crucial for precision machining.

The V-way bed of the lathe is induction-hardened and ground, ensuring longevity and sustained accuracy. It also features a gap bed section, enabling the handling of larger diameter workpieces, a significant advantage for those working with diverse project sizes.

Functionality and Performance

The Jet GHB-1340A provides extensive threading and feed capabilities without the need for frequent gear changes, thanks to its versatile gearbox. This feature simplifies operations and reduces setup time, a boon for high-volume projects. The independent leadscrew and feed rod enhance the machine’s precision and versatility.

The lathe's operational control is augmented by an apron-mounted spindle actuation control, allowing for finer control over machining processes. Additionally, the compound and cross slides are designed with backlash elimination, which is critical for maintaining the precision of cuts over time.

Comfort and Ease of Use

Adjustability is at the heart of the Jet GHB-1340A's design. The adjustable gibs in the carriage and slideways provide a custom fit for the machinist, enhancing both comfort and control. The tailstock, which can be offset for turning tapers, includes an inch-metric graduated quill, adding to the machine’s versatility.

Pros and Cons of Jet 321101AK GHB-1340A Lathe with CBS-1340A Stand

Pros:

- Enclosed Gear Box: Ensures smooth and quiet operation.

- Easy Speed Changes: Eight spindle speeds ranging from 70 to 2,000 RPM.

- Precision: D1-4 spindle supported by high-quality tapered roller bearings.

- Durable Construction: Hardened and ground gears in headstock and gearbox.

- Versatility: Handles a wide range of materials, including aluminum, brass, and steel.

- Gap Bed Section: Allows handling of larger diameter workpieces.

- Adjustable Gibs: Customizable fit for enhanced control and comfort.

- Comprehensive Accessories: Includes 3-jaw and 4-jaw chucks, face plate, tool post, steady and follow rest, and more.

- Ease of Maintenance: Enclosed gear box and constant oiling system.

- Tailstock Adjustability: Can be offset for turning tapers with inch-metric graduated quill.

Cons:

- Weight: At 1,154 lbs, it may be challenging to move and install without proper equipment.

- Price: Higher cost compared to some entry-level lathes, although justified by its features and build quality.

- Size: Requires adequate workshop space due to its dimensions (71 x 32 x 45 inches).

- Single Phase Motor: The 2 HP, 230V, 1Ph motor might limit usage in environments requiring three-phase power.

Accessories and Add-ons

The lathe comes packed with a plethora of accessories aimed at maximizing functionality. These include a 6″ 3-jaw direct mount chuck with top reversing jaws, an 8″ 4-jaw chuck, a 12″ face plate, and a four-way tool post. The steady and follow rest, metric change gear, and splash guard are thoughtful additions that cater to a wide range of machining needs.

Jet 321101AK GHB-1340A Lathe with CBS-1340A Stand Specifications

| Specification | Details |

|---|---|

| Size | 13 x 40 |

| Swing Over Bed | 13 inches |

| Swing Over Cross Slide | 7-25/32 inches |

| Swing Through Gap | 18-3/4 inches |

| Length of Gap | 8 inches |

| Distance Between Centers | 43 inches |

| Spindle Bore | 1-3/8 inches |

| Spindle Mount | D1-4 |

| Spindle Taper with Sleeve | MT-5 (MT-3) |

| Number of Spindle Speeds | 8 |

| Range of Spindle Speeds | 70 – 2,000 RPM |

| Number of Longitudinal and Cross Feed Rates | 40 |

| Range of Longitudinal Feeds | .0018 – .0374 IPR |

| Range of Cross Feeds | .0006 – .0130 IPR |

| Number of Inch Threads | 38 |

| Range of Inch Threads | 3-1/2 – 80 TPI |

| Number of Metric Threads | 23 |

| Range of Metric Threads | .45 – 10 |

| Max Tool Size | 5/8 x 5/8 inches |

| Compound Slide Travel | 2-11/16 inches |

| Cross Slide Travel | 6-5/16 inches |

| Carriage Travel | 35 inches |

| Tailstock Spindle Travel | 3-3/4 inches |

| Taper in Tailstock Spindle | MT-3 |

| Follow Rest Capacity | 2-3/8 inches |

| Steady Rest Capacity | 2-3/4 inches |

| Width of Bed | 7-3/8 inches |

| Motor | 2 HP, 230V, 1Ph |

| Prewired Voltage | 230V |

| Weight | 1,154 lbs |

| Overall Dimensions | 71 x 32 x 45 inches |

| Style | Bench – Geared Head |

| Drive | Geared Head |

Maintenance and Warranty

Jet’s Red Assurance 2-year warranty underscores the company's confidence in its product. Authorized Service Centers across the United States provide quick and efficient service, ensuring that any downtime is minimal. This support structure is vital for professionals for whom machine downtime can mean lost revenue.

Conclusion

The Jet 321101AK GHB-1340A Lathe with CBS-1340A Stand stands out as a reliable, versatile, and user-friendly machine. Its well-thought-out design, combined with a comprehensive range of accessories and robust performance, makes it a worthwhile investment for any machinist.

Whether you are enhancing your home workshop or outfitting a professional setting, this lathe is equipped to meet your needs with precision and efficiency.